(1) Preparation before starting To ensure safe driving, the following inspections should be carried out before starting.

2024 Deutz SerDia 4.0 SerDia2010 14.1.9.3 Highest Level 6 Diagnostic Software

① Check whether all parts of the diesel engine are normal, whether all accessories are connected reliably, and eliminate any abnormal phenomena.

② Check whether the electric starting system circuit wiring is normal and whether the battery power is sufficient.

③ Check the oil level in the oil pan and the injection pump assembly. The oil level should not be lower than the center line of the upper and lower limit marks of the oil dipstick.

④ Check the oil level in the fuel tank.

⑤ Open the fuel tank switch to allow diesel to flow to the fuel pump.

⑥ Use the fuel pump to remove air from the fuel system.

⑦ Check the cooling system and add enough water.

⑧ For diesel engines with power booster pumps, check whether the booster pump has sufficient circulating oil. It must not run idle. The oil suction vacuum at the booster pump inlet must not be higher than 0.02MPa, and the oil suction pipeline is not allowed to leak.

⑨ For new engines or diesel engines that have been parked for more than 5 days, the crankshaft should be rotated 3 to 5 times before starting.

⑩ For diesel engines that are parked for emergency use, in order to facilitate rapid start-up and operation in case of emergency, they should be started and tested every 3 to 5 days during the parking period until the water and oil temperatures reach above 60°C.

Deutz Diagnostic Tool Communicator for Deutz Engine DECOM Controllers

(2) Starting the diesel engine

After the preparatory work before starting is completed and confirmed to meet the requirements, it can be started. The clutch should be disengaged during starting. The starting steps are as follows.

① Turn the ignition switch (see Figure 1-35) to start the diesel engine.

Note: The connection time should not exceed 5 seconds each time to protect the starter battery; after each start failure, it should be stopped for 60 seconds before starting again. If it fails three times in a row, the cause should be identified and the fault should be eliminated before starting again. Once the diesel engine is started, the lock switch should be turned back to its original position immediately.

For supercharged and supercharged intercooled diesel engines, since a supercharger is used, the engine should be idled for 3 to 5 minutes after each start to allow the oil pump to work properly and to build up the necessary oil pressure, ensuring that the pressure reaches the supercharger bearing at the top of the diesel engine.

② After the diesel engine is started, the oil pressure should be checked immediately by the oil pressure warning light and oil pressure gauge on the instrument panel. If there is any abnormality, the cause must be identified and the fault must be eliminated.

③ After the diesel engine is started, it should be idled for 3 to 5 minutes. It is strictly forbidden to accelerate or throttle immediately after starting.

④ When starting in winter, the air preheating button can be pressed, but it should not exceed 40 seconds.

(3) Cold start of diesel engine

① Introduction to the function of low-temperature starting device The currently produced “low-temperature start type” series diesel engines mainly use the intake air preheating method to improve the low-temperature starting performance of diesel engines. The CA6DE3 (BF6M1013) series engines use two intake air preheating methods: one is to ignite diesel to heat the cold air entering the engine intake manifold (flame preheater heating); the other is to use electrical heating (PTC air heater heating). The usage of both heaters is briefly described below.

a. Flame preheater. This device heats the intake air by igniting diesel injected into the intake manifold. This device automatically activates when the engine’s coolant temperature falls below 0°C. When starting the diesel engine, the operator first places the ignition key (YI=Y) in the preheat position. After approximately 26 seconds, the preheat indicator light turns off, and the operator can start the engine.

b. PTC air heater. The PTC air heater (shown in Figure 1-36) stores heat generated by electrical energy in the heater. During startup, hot air enters the cylinders first, ensuring a smooth engine start. When the driver wants to start the diesel engine, he or she should first press the preheat switch. After 6 minutes, the buzzer will sound, indicating that the preheater is finished. The driver can then reset the preheat switch and start the engine.

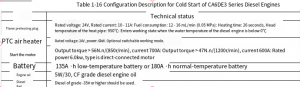

② Cold Start Components: The CA6DE3 series has a specially developed air heater. To ensure low-temperature starting performance, the vehicle’s engine oil, diesel, battery, and other spare parts must be configured according to relevant requirements. Specific requirements are shown in Table 1-16.

③ Precautions

a. The flame preheater’s glow plug is a consumable part with a normal lifespan of 400-500 cycles, or approximately two years. Therefore, the glow plug’s operating condition should be regularly checked. If the glow plug is operating normally during starting, the temperature of its exposed portion should be significantly higher than that of surrounding components (by feel). If any abnormality occurs, the heat pipe resistor may be blown, and the glow plug should be replaced.

Deutz Serpic 2012 EPC Download & Installation Service Finial Version

b. After each start, ensure that the battery is fully charged to ensure a smooth start. c. When starting the diesel engine at low temperature after a long period of inactivity (more than 24 hours), the oil pump should be manually pumped several times before starting. At the same time, the residual air in the diesel filter should be released to keep the oil circuit clear for smooth starting.

(4) Operation of the diesel engine

① After starting the diesel engine, it should not be operated at full load immediately. Instead, the diesel engine should be heated by running it at low and medium speeds.

② During operation, the oil pressure and cooling water temperature should be constantly monitored. Full load operation is permitted only when the water temperature reaches above 60°C and the oil temperature reaches above 65°C. During normal operation, the oil pressure should be between 0.2 and 0.5 MPa, and the cooling water outlet temperature should be controlled within 95°C.

③ Always listen to the diesel engine for any abnormal noises. If any are detected, the engine should be stopped and checked immediately. After the cause is identified, it can be restarted and operated.

④ Always pay attention to the sealing condition of the oil and water connections; if there is any leakage, it should be handled immediately to prevent waste and environmental pollution, and oil or water should be replenished in time.

⑤ New or overhauled diesel engines need to run for 2000km at medium and low speeds and light loads before they are allowed to be used at full load.

⑥ The injection pump has been adjusted and the limit screws have been sealed before the diesel engine leaves the factory. Users are not allowed to remove the seals and adjust them at will during use. During operation, it is strictly forbidden to accelerate – shut down – coast – shift gears and then use the clutch to start the diesel engine.

(5) Shutdown of diesel engine

① When the diesel engine is stopped, the load and speed must be gradually reduced to idle speed, and it must idle for 5 minutes before stopping. It is strictly forbidden to stop at high speed unless it is an emergency to prevent the high temperature of the turbine from being transmitted to the floating bearing and the compressor seal ring, causing a supercharger failure. At the same time, it should be noted that the idling time should not be too long (generally not more than 20 minutes), as it is easy to cause oil leakage.

② When the temperature is below 5℃, if antifreeze is not used, the cooling water should be drained immediately to prevent the parts from freezing and cracking.

③ After each shutdown, any faults found during operation must be promptly eliminated and necessary inspections carried out.

④ If the diesel engine is not used for a long time, it must be cleaned and oil sealed as necessary to prevent rust.

(6) Diesel engine running-in A new or overhauled diesel engine must be run-in before it is allowed to run at full speed and full load. The running-in mileage on the vehicle is 2500km. Among them: 0~200km, empty vehicle running, speed not exceeding 40km/h; 200~1500km, load not exceeding 3t, speed not exceeding 60km/h; 1500~2500km, load not exceeding 3t. During the run-in period, the engine oil should be changed three times, at 500 km, 1000 km, and 2500 km, respectively. The air filter element and dust collector should also be cleaned.

At the end of the run-in period, the following maintenance should be performed:

① Clean the diesel engine oil pan, change the lubricating oil, and clean the oil pan oil filter;

② Tighten the oil pump drive gear nut;

③ Check the torque of the main bearing cap bolts;

④ Check the torque of the connecting rod bolts and the cylinder head bolts;

⑤ Check and adjust the valve clearance;

⑥ Replace the oil filter and remove dust from the air filter element;

⑦ Check the fuel injection advance angle; tighten the injection pump coupling bolts;

⑧ Remove the injection pump speed limiter screw, check the belt tension, and adjust it appropriately;

⑨ Tighten the screws connecting the supercharger to the exhaust manifold;

⑩ Check the suspension cushions for cracks and loose nuts.