This article explains how to adjust the extended bucket wear pads for 3CX – 4CX – 214 – 214e – 215 – 217jcb backhoe loaders

06.2025 JCB ServiceMaster 4 v25.3.3 Diagnostic Software with SW Files Download and installatiom

The Extradig dipper wear pads are bolt-on replaceable

items. They support and guide the inner dipper section

during extension and retraction. The following procedures

explain how to inspect, and where applicable, adjust the

pads.

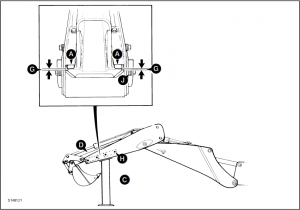

There is a front and rear set of pads, each set comprises top

wear pads A and bottom wear pads B

The top wear pads A are not adjustable and must be

replaced with new pads once they have worn to their limit.

See Inspecting the Top Wear Pads.

The bottom wear pads B are adjustable and take up the

wear on both the top and bottom pads. They must also be

replaced with new pads once they have worn to their limit.

See Adjusting the Bottom Wear Pads.

New wear pads A and B must be replaced as a set and

fitted by a qualified service engineer.

Inspecting the Top Wear Pads

1

Park the machine on level ground. Engage the parking

brake and put the transmission in neutral.

2

Position the boom and dipper as shown at C. Retract

the Extradig dipper D. Make sure that the bucket is

clear of the ground and the dipper is supported.

3

Stop the engine and remove the starter key.

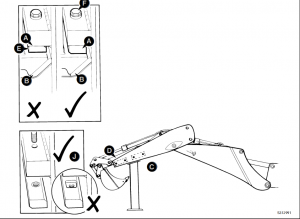

Renew the pads when, or before they are worn down to the

depth of the recess/chamfer as shown at E. If the pads are

worn near to their limit then inspect them more frequently

than recommended in the Service Schedules. To avoid

damage to the dipper or wear pad make sure the pads are

fitted the correct way round as shown at J.

06.2025 JCB ServiceMaster 4 v25.3.3 Diagnostic Software with SW Files Download and installatiom

Torque Settings

Item Nm kgf m lbf ft

F 56 5.7 4

Adjusting the Bottom Wear Pads

1

Park the machine on level ground. Engage the parking

brake and put the transmission in neutral.

2

Support the boom and dipper as shown at C.

3

Stop the engine.

4

Clean the sliding faces of the inner dipper with a

suitable solvent.

5

Start the engine. Retract the Extradig dipper D. Make

sure that the bucket is clear of the ground and the

dipper is supported.

6

Stop the engine.

7

With grease, mud etc. removed from the sliding faces

visually check the gap between inner dipper and top

wear pad A, as shown at G. The gap should be no

greater than 1.5 mm (1/16in)

If the gap is greater than 1/

16in (1.5 mm) then adjust as

follows:

a

Remove one adjusting bolt H and discard one

washer J.

b

Refit and tighten bolt H.

c

Repeat the procedure for the remaining 3 adjusting

bolts H on the same side of the dipper.

d

Visually re-check the gap is no greater than 1.5 mm

(1/16 in) as shown at G, if necessary repeat steps a

to c for the other 4 bolts H on the opposite side of

the dipper.

e

Make sure that the inner dipper seats central to the

sides of the outer dipper.

Note: Remember to alternate sides each time an adjustment

is made.

Note: When all the adjusting washers J have been removed

and the clearance is greater than 1.5 mm (1/

16

in), then wear

pads A and B must be replaced as a set and fitted by a

qualified service engineer.

When the adjustments have been completed, apply Waxoyl

to the runners of the inner dipper.